|

NCR by Estes F62 Darkstar motor production

I started a new thread so not to go OT in Bob's history thread.

F62s were very fine single use motors, especially memorable because another single use smokey available was the AT F14, so the F62 was a wonderful alternative, plus I recall the delays being spot on. I only have four left :( Matt Steele mentioned that 17,000 were fired in development testing which staggers the imagination. Matt, can you divulge total number produced? F62 post |

Thanks for the compliments. Between Scott Dixon, Mike Dorffler, Dan Kafun and I, we worked very hard to make a great hobby composite motor. We paid a lot of attention to the delays to make sure they would work well.

I'd prefer not to disclose the total number of motors made, but is was "lots and lots more" than 17,000, as you might guess. Matt |

Just from simple math if they tested 1% of production it would be 1.7 million motors, or if 10% it would be 170,000 motors.

One could reasonably guess it would be somewhere between the two; that is a LOT of F62's ! |

I saved one each F62-4 and F62-6 and put them up with a few black powder Centuri and Estes Diamond packs. Sad it must have been more cost effective for Estes to contract Aerotech the next time they entered the composite market.

|

The 17,000 F62 motors tested were all pre-production qualification motors, so you can't draw any conclusions between that number and production testing. We had to test 17,000 before we were satisfied to release the first production motor to the market.

Matt |

Quote:

Were all of those fired in test stand to generate a thrust curve? |

No, the motors had very reproducible time-thrust curves.

The testing was done to establish statistically significant reliability values. We had to be sure the motor worked as designed under a wide variety of conditions (0 degrees F to 120 degrees F, for example). We didn't want any problems to crop up after we released them (like what happened to Estes when they released the infamous D13s that had a propensity to fail catastrophically). Matt |

Quote:

I guess you guys had...(wait for it) Money to burn! ;) |

I think I saw a figure that was related to a Tunik Q&A that was 6000 delivered motors. I remember feeling that was a relatively small number.

Much of what he did was tax loss destruction of manufacturing assets, tooling and stuff that really should have ended up in a museum. For example he dismantled Vern's house. Jerry |

Wasn't there fire at Estes that contributed significantly to the decision to exit the mid-power market?

|

I think most of us are SOOOOOOOOO glad that Estes is owned/managed by a real HOBBY company now instead of the last 'disaster at the helm' that had no previous hobby experience whatsoever.

|

Matt,

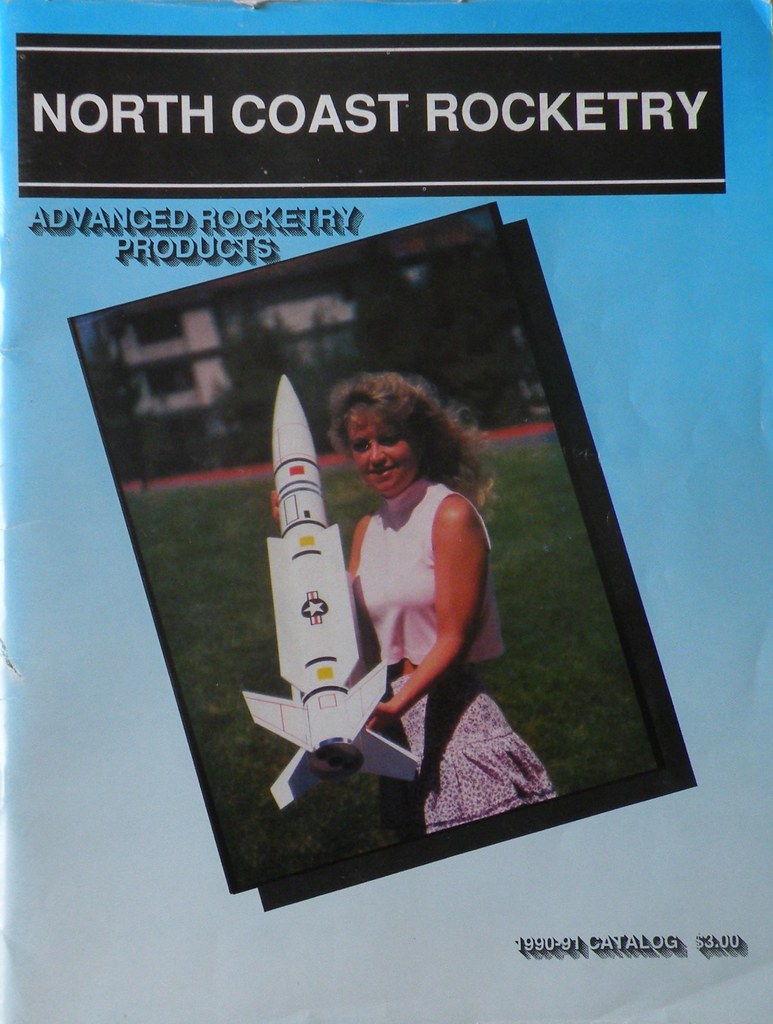

Thanks for the reply. As someone who reentered the hobby in 1989, North Coast was a big part of the move to high power. My North Coast catalogs of the period ae well-worn, and my NCR Corporal was my first high power rocket, built in 1991. I have flown a few 20+ year old composite motors with good resuts. I was wondering if you have a feel for how the Darkstars are aging and if thought was given to that when they were designed. |

Quote:

TMI TMI !!! :eek:   :D . |

Mick Gilette of RDS (RIP) also used the models approach. Probably sooner.

https://www.rocketreviews.com/rocke...hnnie-paul.html |

Quote:

Yeah, but 5x7 didn't mention his well worn catalogs... ;) |

17,000 motors tested in development???

That totally surprised me. During the short time I was at AeroTech, I would say that most of the motors we developed were tested maybe 20-30 times (including the certification firings) before they were on the street (or, uh, er playa). Now bear in mind these were mostly reloads, and if you have say a Redline 38/240 reload worked out, pretty much you have the Redline 38/360 reload worked out too. This was of course unless there were bugs... Matt, did the Darkstars use pre-cut delay lengths, rather than the drilled delays seen on AeroTech motors of the same era? |

Using the models was genius, it instantly communicated it was a legitimate hobby for adults!

|

That 871 catalog (with a 88 price sheet) was the first NCR catalog I received. As I recall, in the early days I purchased a Corporal (disappeared on a F10), a Phantom 4000, a Quasar II (staged BP F motors!) and . . . hmmm, there must have been one or two more.

Two members of my old Tripoli section, LIARS, had their photos used in a later catalog. They were way nerdy guys and not cover-model material! ;-) |

1) Jerry's production numbers are wrong. It would never be Barry Tunick's methods to ever release numbers he considered proprietary. In addition, it would be silly to test that many motors and then release a number less than that for sale.

2) The release of the 4th Star Wars movie fed into the eventual demise of NCR at Estes. The company invested a great deal into Star Wars products at the expense of other products. 3) Yes, NCR had some memorable and eye-catching covers, didn't we? Matt |

1) The Dark Star delays were pre-cut to a specific length on an automated remote cutter, and then bonded (not just inserted) into the ejection plug; this prevented some of the issues that Aerotech experienced with hot gasses blowing past the delay and igniting the black powder charge prematurely.

2) Both the propellant and delay formulations were designed by Scott Dixon with a minimum of a 25 year shelf life. The motors should fly well long past the 25 year mark, but there was a conscious effort to formulate with long term aging in mind. Matt |

Quote:

We used the attractive young ladies as models because it was the easiest way to communicate the large size of the rockets - something people were not familiar with - these were not toys - and the target audience was sure to look at the rockets.....eventually. We had only one complaint over the whole time on our catalog covers, and it came from a particularly obnoxious mother of a teenager. Since she would never buy the product, we never worried about her concerns. Matt |

Quote:

I might have complained that there weren't enough photos with Traci.... eventually. As soon as put the catalog away. :D |

I enjoyed the catalogs and the products. When I visited Huntsville to fly with HARA, I kept my eye out just in case I spotted one of the models.....not the rockets. ;)

I have 2 versions of the Corporal. Without going home and looking, it seems like one is ~ 1.8" dia. and the other is ~ 2.6". What led to the change? |

Is there anything preventing Estes from simply re-releasing the motors? All the engineering is done. When they re-release kits they do all new molds now since they produce at a contract shop in China.

|

Quote:

Great news, and I had forgotten Scott Dixon was involved. If I get the guts I may fly my Quasar NG on an F62-4 at LDRS :) Do you think you could have made a white that lasts? I have some old AT grains that have swelled to about 150% original size. Do you think you could have made a white that lasts? |

Quote:

I just liked the bigger size model (2.6" diameter) better. Matt |

Quote:

1) Scott Dixon made all the propellant and delay for Estes. He had the formulation, and Estes does not. 2) There is no one at Estes who knows how to make composite propellant now. There are very few people who know how to make production-sized batches of AP/HTPB propellant. It is not as straightforward as scaling up what most EX folks do. It was also more sophisticated than Aerotech's methods (though more expensive than Aerotech's methods). The process used Vulcan Systems equipment that is no longer available to Estes. And, Scott doesn't want to do small motors or hobby motors anymore. He does work that pays much, much better. 3) The cases used some special engineered materials and were molded in the US. As far as i know, those materials are not available in China, and not able to be exported. So, no, Estes can't do it anymore. The current version of NCR could do something very similar from a technical standpoint, if I were so inclined, but the capital costs of re-starting production and re-certifying the motors is cost-prohibitive. Sorry! Matt |

Scott Dixon's version of the bright white flame/white smoke "Dragon Fire" propellant was formulated to avoid the aging issues seen in Aerotech's White Lightning propellant.

Despite not having finished his college degree, Scott Dixon is a brilliant chemist and formulator. He holds patents on some unique aspects of propellants. Matt |

Quote:

Jerry |

Quote:

|

I attended many launches in the period when the NCR F62s were out and I never saw or heard reported an F62 having a Cato. Do you recall the reliability of the 17000 fired, (about how many failed) and we're changes made to the design through the process of firing all those, or was that as you say just to prove the reliability of the production design?

Thanks again for answering questions about it, it's facinating. I am also curious about the chamber pressure they run at. |

Sounds like Scott Dixon himself is best positioned to restart production with existing tooling, devices, formulas, likely for a non-consumer application.

|

Quote:

Will be interested to see Matt's response. I too haven't ever heard or seen a problem. I have flown many....still have a half-dozen left. Best mid power motor EVER! Always easy to ignite (even now), impressive visual display, and spot on delays. Love 'em! -Eric- |

My observation is they have a zero end user failure rate. Normal Estes BP is somewhere near 1% on an anecdotal basis, combines early batch manufacturing issues and storage issues. The only reason we no longer see MPC B's 13mm is the guy who got them moved the trucks to the north coast and exposed them to repeat winters. Had he simply stored the trailers in CA we would have had a continuous supply for the past 20 years.

|

Quote:

We had no failures in the last 11,000 we fired, if I recall correctly, we uncovered a problem in testing that first 5,000 that only resulted in 2 or 3 failures, but it needed to be resolved before they could be released to the public. The whole time that I was at Estes, i don't recall getting a report of a motor cato from ones we had sold to the public. Matt |

Quote:

That's pretty darn impressive. |

Quote:

BTW what was the failure mode you observed in the first 5000? |

The end result of very good design, along with sufficient capital invested in quality ingredients, components, and consistency in production method. :cool:

|

Too bad it didn't result in more than just the F62 motor.

Would be nice if they were still produced along with the planned G70. Instead of ultra-reliability, I prefer a myriad of choices instead. |

Quote:

The NCR I have issue with is the Pearson version. NCRBE kits obviously have a following. But the F62 was really Vulcan by Estes (VBE). Awesome tech buried by Tunik. |

| All times are GMT -5. The time now is 06:15 PM. |

Powered by: vBulletin Version 3.0.7

Copyright ©2000 - 2024, Jelsoft Enterprises Ltd.